Taiko Kikai's gear pump is provided with segmental gears, which continuously contact each other on one point, as its standard.

Segmental gear eliminates confinement phenomena, which occurs on conventional involute gears, to realize the positive-displacement pump that has small noise, small vibration, and long lifetime. Taiko Kikai's gear pump is used for transferring, for example, lubrication oil, fuel oil, and chemical liquid.

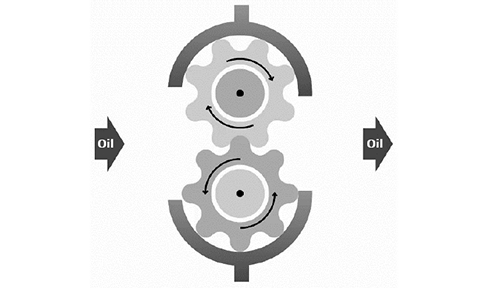

Gear pump is a kind of positive-displacement pump that captures the liquid into the gaps formed by the meshing of the gears rotating inside the casing so as to let the liquid go along the inner periphery of the casing through from the suction-end to the discharge-end.

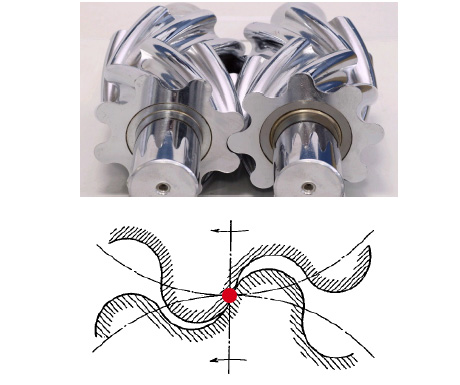

Taiko Kikai's gear pump is provided with segmental gears.

Continuous one-point contact prevents confinement phenomena

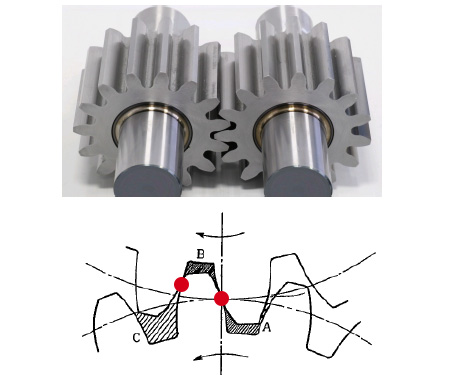

Confinement phenomena

Two-point contact of gears lets the liquid be compressed (A→B) and expand (B→C), which causes vibration and noise.

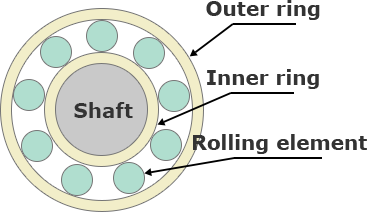

Bearing is a mechanical component that literally bears the shaft

Bearings are categorized into the following two types with their configurations

The bearing contacting a shaft to have a sliding motion on the contacting surface

The bearing provided with rolling elements, such as balls or rollers, to have a rolling motion

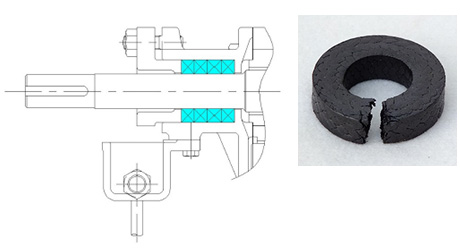

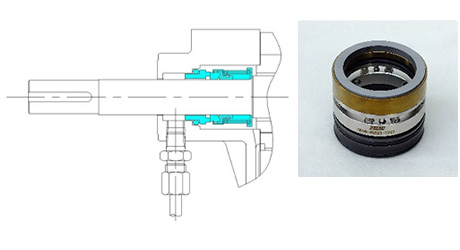

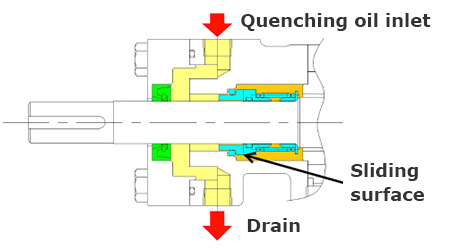

Oil quenching type is used when the handled liquid is fuel oil.

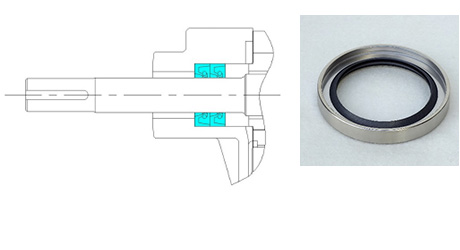

The residue is left when handled liquids, such as fuel oil, exuding from the sealing surface evaporates. This residue deposits on the sliding surface, which can lead to leakage from the seal.

Filling the atmospheric-end of the mechanical seal with some lubrication oil keeps the sliding surface from the atmosphere to prevent the acidization of the fuel oil.