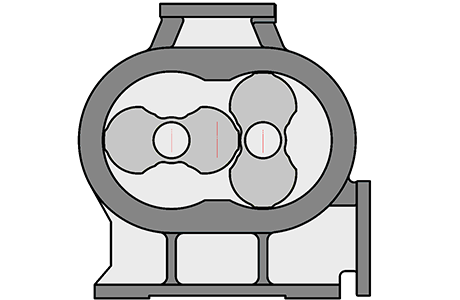

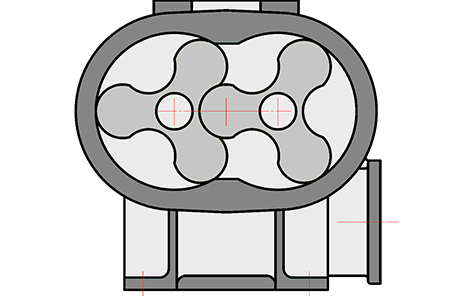

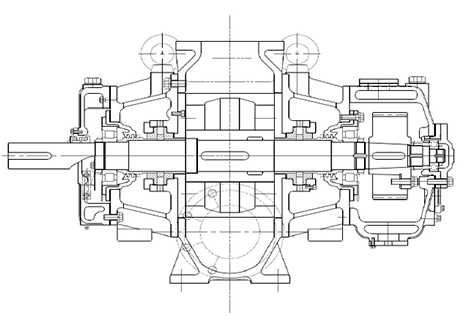

The form of the impeller varies in the number of the lobes, twin-lobe or three-lobe, according to the purpose. Available bore size ranges from 20A to 700A.

Taiko Kikai’s blowers are manufactured to meet the unique requirements from the customers. This enables Taiko Kikai’s blowers to handle a wide range of gases, from air to special gases.

Taiko Kikai’s blowers are selected for a variety of purposes, including water treatment, pneumatic transferring, gas circulation, and gas separation with PSA.

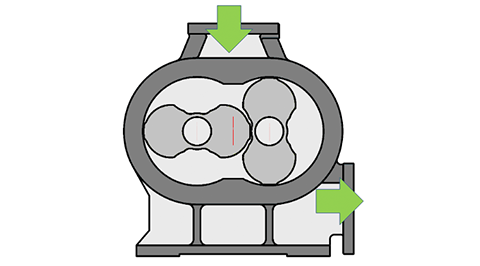

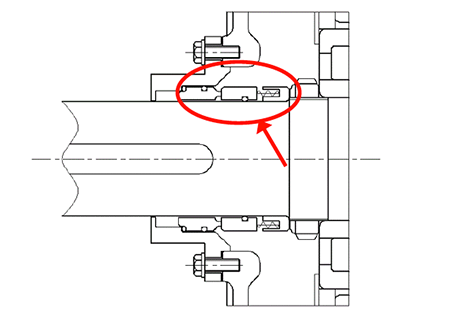

Roots blower is a kind of positive displacement pumps. The impellers, which keep a film-thin clearance between each other, rotate in the casing without contacting each other to transfer the gas from the suction end to the discharge end through the inner periphery of the casing.

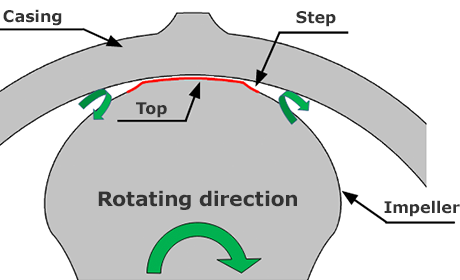

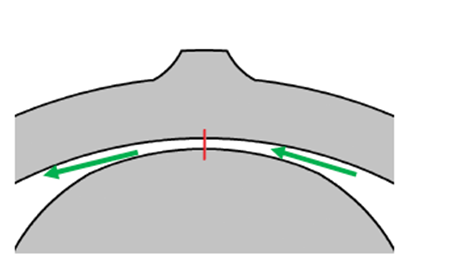

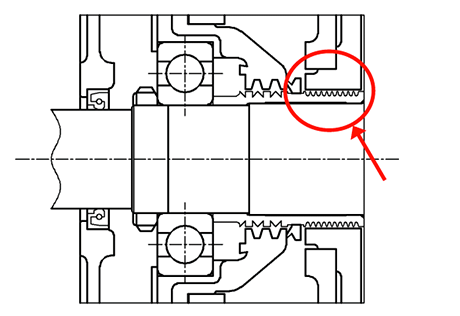

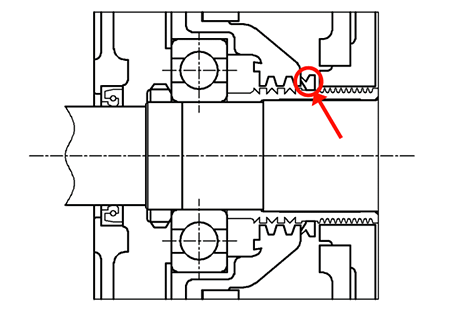

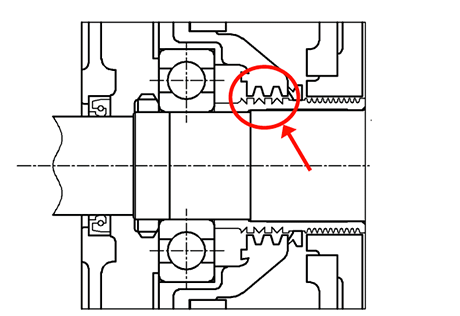

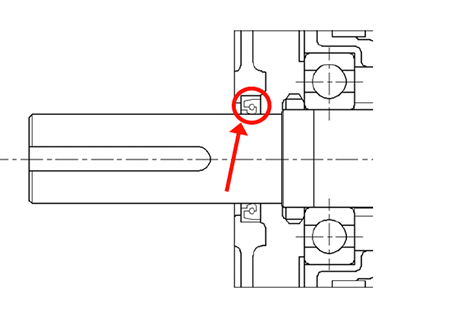

The tip of the impeller, called a top, and the inner periphery of the casing are configured to form together a face seal. The step generates currents swirling against the flow of the gas, which goes against the rotation direction of the rotor, to decrease the internal leakage amount. This achieves a high operating-efficiency and an effect of energy-saving.

An arch-shaped top may lead to a larger internal leakage amount due to its poor sealing effect.

| Item | Twin-lobed blower | Three-lobed blower |

|---|---|---|

| Discharge / rotation | 4 times | 6 times |

| Theoretical flow rate | ◎ | ◯ |

| Pulsation pressure | ◯ | ◎ |

| Compression noise | ◯ | ◎ |

| Covered pressure range | ◯ | ◎ |

| Pump size | ◎ | ◯ |

Twin-lobed type blower has a large internal capacity, thus has the smaller body compared to three-lobed type. On the other hand, three-lobed type blower has lower values of pulsation pressure, compression noise, and internal leakage amount.

Many circular grooves are formed, vertically to the gas flow, on the surface of the shaft and the bore of the casing in a parallel manner. This configuration makes a large pressure loss when the gas goes through the grooves, which expands the volume of the gas to provide a sealing function.

The rubber-made seal that is configured to provide a sealing ability by fixing its bore to the shaft and letting its lip slide on the end surface of any static part.

Concentric oil grooves are formed on both the outer surface of the shaft and the bore of the bearing housing. This configuration keeps some lubricating oil in the grooves to provide a sealing effect.

Nitryl Butadiene Rubber (NBR) made seal configured to provide, with its sliding contact surface, a sealing effect.

Oil film formed on the sliding portion achieves low friction and small abrasion.

Widely applicable, and easily available due to its low price.

Rotating seal ring and static seal ring are configured to slide on each other to provide a sealing effect.

Extremely small leakage amount.

Usable even under severe conditions, including high temperature, high pressure, high speed, and cryogenic temperature.

Long life due to low friction on the sliding parts.

Single mechanical seal on shaft-end,

Double mechanical seal on shaft-end,

Double mechanical seal on each stuffing box, and/or Double dry gas seal on each stuffing box are selected in accordance with the required specifications.

| Material | Feature |

|---|---|

| Gray cast iron | Standard material of pump’s main body |

| Nodular graphite cast iron | High rigidity, High-pressure-proof |

| Cast carbon steel | High rigidity, High-pressure-proof |

| Cast iron for low temperature and high pressure | High rigidity, High-pressure-proof, Low-temperature-proof (down to -45℃) |

| Cast stainless steel | Martensitic stainless steel (equivalent to SUS403) Low coefficient of thermal expansion, Magnetic |

| Austenitic stainless steel (equivalent to SUS304) High corrosion-resistant, Low-temperature-proof (down to -196℃), Non-magnetic |

|

| Austenitic stainless steel (equivalent to SUS316) High corrosion-resistant, Low-temperature-proof (down to -196℃), Non-magnetic |

|

| Duplex stainless steel (equivalent to SUS329J1) High corrosion-resistant, Low coefficient of thermal expansion, Magnetic |

|

| Cast bronze | Anti-spark |

| Stainless steel bar | Martensitic stainless steel Low coefficient of thermal expansion, Magnetic |

| Austenitic stainless steel High corrosion-resistant, Low-temperature-proof (down to -196℃), Non-magnetic |

|

| Duplex stainless steel High corrosion-resistant, Low coefficient of thermal expansion, Magnetic |

|

| Structural carbon steel | Standard material for rotor shaft |

| Chromium-molybdenum steel | Shaft material (high rigidity) |

| Standard material for timing gear | |

| Rolled steel for general structure | - |

| Part | Corrosive | |

|---|---|---|

| For non-corrosive use | For corrosive use | |

| Casing | ・Standard material (FC200) | ・Stainless steel ・Electroless nickel plating ・De Fric coating |

| Impeller | ・Standard material (FC200) | ・Stainless steel ・Electroless nickel plating ・De Fric coating |

| Shaft | ・Standard material (RB,RC:SCM440H) (RD~RG:S45C) |

・Stainless steel |

| Side plate | ・Standard material (FC200) | ・Standard material (FC200) ・Electroless nickel plating ・De Fric coating |

| Side cover | ・Standard material (FC200) | ・Stainless steel ・Electroless nickel plating ・De Fric coating |

| Sleeve | ・Standard material (S45C) | ・Stainless steel |